Solar Connector

Multi-Contact, 4 Millimetre Solar Connector, 1000V

H Branch Solar Panel Connector, 2 to 1

Y Branch Solar Panel Connector, 2 to 1

H Branch Solar Connector, 3 to 1

Y Branch Solar Connector, 3 to 1

H Branch Solar Module Connector, 4 to 1

Y Branch Solar Panel Connector, 4 to 1

H Branch PV Panel Connector, 5 to 1

Solar Photovoltaic Fuse Connector, 5A/10A/25A/30A

Solar Module Bypass Diode Connector, 10A/15A/20A/30A

Solar connectors, also known as photovoltaic connectors, are electronic components used to connect solar panels to inverters, playing a crucial role in the setup. In a solar power system, solar panels convert sunlight into electricity, while inverters convert this direct current into alternating current to meet the demands of residential, industrial, and commercial applications. Solar connectors ensure the smooth transfer of energy generated by solar panels to the inverter, avoiding overheating and energy loss throughout the conversion process.

Furthermore, solar connectors, also referred to as terminal blocks or quick connectors, are essential components that facilitate the interconnection between various parts of photovoltaic systems such as modules, junction boxes, controllers, and inverters. They are typically designed with new polymer materials that are heat-resistant, insulating, and flame-retardant.

The functionality of PV panel connector extends beyond physical connections; they also protect the connected parts to ensure the stability and safety of the system. They are commonly located between the array of solar panels forming a photovoltaic array and the solar charge controller, serving the purpose of connecting and safeguarding the photovoltaic components.

The Main Types of Solar Connectors

Direct Current Solar Connectors

Direct current solar connectors are used to connect the direct current output terminals of photovoltaic modules to the direct current power system. They can be categorized into various types such as copper body DC connectors, PPO material DC connectors, and PC material DC connectors. Copper body DC connectors are the most common type, typically used in high-power applications, relatively more expensive but with a long lifespan and wide applicability. PPO material DC connectors and PC material DC connectors have good heat resistance and corrosion resistance due to their material properties.

Alternating Current Solar Connectors

Alternating current solar connectors are used to connect the alternating current output terminals of power generators to the alternating current input terminals of the distribution network. They include not only plugs but also sockets, connecting cables, and covers. The classification of alternating current connectors is similar to that of direct current connectors, with common types being copper body AC connectors, PPO material AC connectors, and PC material AC connectors. Their advantages and disadvantages are similar to those of direct current connectors.

MC4 Solar Connectors

MC4 solar connectors are one of the most commonly used connectors for polycrystalline silicon solar panel modules. Due to their convenient installation, good waterproof performance, high temperature resistance, and corrosion resistance, they are widely used in photovoltaic power stations. MC4 connectors consist of three parts: connector body, inner core, and rivet. The connector body materials include PPO and PA66.

Tyco Solar Connectors

Tyco solar connectors are widely used in the field of photovoltaic power stations and are predecessors of MC4 connectors. Tyco connectors have excellent materials, long service life, good cold resistance, and a wide range of operating temperatures. After years of practice and application, Tyco connectors have gradually been replaced by MC4 connectors.

Working Principle of Solar Connectors

Solar connectors are special connectors used to connect photovoltaic modules to other electrical equipment, primarily converting solar energy into direct current and transmitting it to inverters or the power grid for storage or use.

When using solar connectors, photovoltaic modules convert sunlight into direct current, which is then transmitted to the connector's plug. The lamellas in the plug ensure that the current flows normally into the socket and connects with other electrical equipment. Through Solar connectors, direct current can be converted by inverters and transmitted to the power grid for household or commercial use.

The most common industry standard for Solar connectors is MC4. MC4 stands for "Multi-Contact, 4 millimeters", referring to the 4-millimeter diameter of the connector contact pins. MC4 is designed to withstand wind and rain, resist ultraviolet radiation, and withstand harsh environments to provide long-term secure connections.

Applications of Solar Connectors

Although the cost of solar connectors is relatively small in the overall photovoltaic system, they have various applications throughout the system, including junction boxes, combiner boxes, modules, and inverters.

Solar connectors are crucial for photovoltaic systems to ensure electrical efficiency, safety, weather resistance, scalability, ease of installation and maintenance, and compatibility between components. By providing safe and reliable connections between solar panels and other components in the system, Solar connectors minimize power losses and maintain overall system efficiency.

Photovoltaic connectors also prevent potential hazards such as arcs or short circuits and help withstand environmental conditions such as ultraviolet radiation, extreme temperatures, and moisture. A high-quality connector should be able to maintain the lifespan of a solar photovoltaic system (approximately 25 to 30 years).

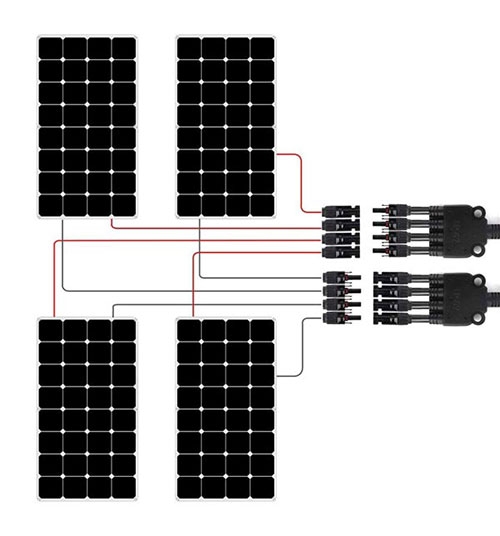

Solar connectors facilitate easy expansion of solar arrays, enabling serial or parallel configurations for flexible system designs. They simplify installation, maintenance, and compatibility with different brands of solar panels and components.

How are Solar Panel Connectors Used?

Understanding the proper utilization of solar panel connectors is essential for anyone with a photovoltaic (PV) system. In this guide, PowerHome provide instructions on attaching solar connectors to wires, securing or releasing them, and incorporating them into series, parallel, or series-parallel configurations.

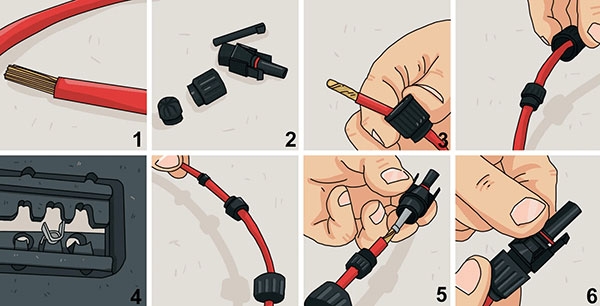

- Following careful removal of the old connector, such as by using a cable cutter to cut it off, strip approximately ½ inch of insulation from the cable tip.

- A standard connector consists of four primary components. Unscrew the cap to disassemble it.

- Then, thread the wire through the cap, repeating the process with the cable gland.

- Proceed to insert the pin: secure it within the appropriate slot of the crimping tool, then insert the exposed end of the cable into the cavity. Gently holding it in place, use the tool to crimp the pin onto the wire.

- Now, connect the main component with the remaining part of the connector by screwing them together until they meet at the center.

- The final step involves securing the connection. Lightly tug on the connector to verify its stability at the cable's end.

(1).png)

(1).png)