As long as there is enough wind, a wind turbine generator can spin up and produce electricity, the more wind the faster it spins. Sometimes wind turbines can be damaged or even self-destructed due to over-revving, which is extremely dangerous. According to the normal safety requirements, the wind turbine controller must be installed with a dump load. PowerHome will bring you a detailed introduction of the role of dump load in the wind turbine controller.

What is a Dump Load?

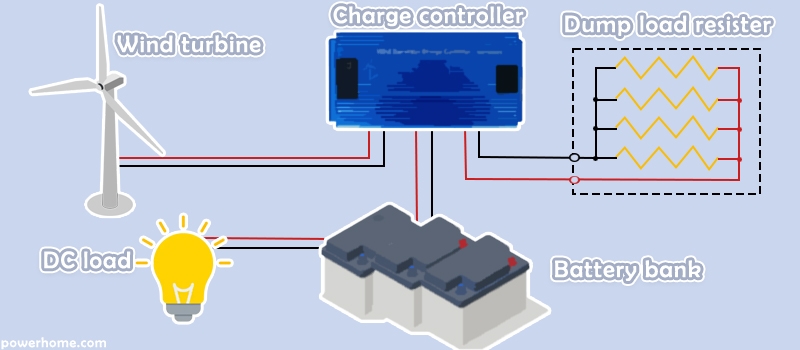

In wind power systems, a dump load is a device, usually a resistive load, used to consume excess electrical energy. It’s also known as diversion load and dummy load. When the wind speed is too high and the generator produces more power than the battery needs to be charged or the system consumes, the dump load is activated to receive the excess power to prevent overcharging the batteries and overloading the system.

Modern small and medium-sized wind turbines for home use generally have several braking methods, including electromagnetic brakes, mechanical brakes, side deviation protection function and so on, while the main function of the dump load is to prevent the battery from being overcharged. In wind turbine controllers, the dump load can assist other components in managing the generator's output power and protect the system from high voltages and over currents caused by sudden increases in wind speed. Specifically, a wind controller with a dump load plays several roles in a wind turbine system:

- Protecting against battery overcharging: When wind speeds are high and the generator produces more power than the batteries need, the turbine generator controller directs the excess power to an unloading resistor or load that reduces the charge to the batteries and prevents them from being overcharged.

- Protecting the generator: In strong wind conditions, the generator may produce excessive voltage and current, which can damage the generator or other parts of the system. Wind turbine controllers can protect the generator from overload damage by reducing the load on the generator.

- Improve system efficiency: By managing the output of the generator, a controller with dump load can help improve the overall efficiency of the system by ensuring that the generator operates at its optimal operating point, rather than at too high a power output that could lead to overcharging or damage.

- Extended system life: By preventing overcharging and overloading, the wind turbine controller helps to extend the life of the batteries and other system components.

How Does Dump Load Work in a Wind Turbine Controller?

The significance of dump load for wind turbine controllers is that it provides a safe way to dispose of excess power while protecting the batteries and other components of the generation system from damage. The working principle and steps for dump load are as follows:

- Monitoring output: The wind controller monitors the output voltage and current of the turbine generator in real time. These parameters will change with the wind speed.

- Setting dump threshold: According to the design requirements of the system, set the upper limit of charging voltage and current of the battery as the threshold of dumping. When the battery is close to full or reaches the set upper limit of voltage and current, the system will start the unloading process.

- Activate dump load: Once the threshold is reached, the controller will activate the dump load. This is usually accomplished through a relay or switch that connects the generator's output circuit to the resistive load.

- Consuming excess power: The dump load begins to consume excess power, converting it to heat. This reduces the current flow to the batteries and prevents them from being overcharged.

- Adjusting dump power: In some systems, the power of the dump load can be adjusted to accommodate different levels of excess electrical energy. This can be done by changing the value of the resistance connected to the load or through PWM technology.

- Stop dumping: When the wind speed drops and the generator's output power returns to normal levels, the controller shuts down the dump load, stopping the consumption of electrical energy and allowing it to flow normally to the batteries.

Dump loads are an important safety feature in wind turbine systems that help protect the long-term stability and reliability of the system. The correct configuration and use of dump loads can significantly extend the life of the batteries and ensure that the system operates safely in a wide range of wind conditions.

Dump Load in PWM and MPPT Controllers

The PWM controller controls the output voltage and current by adjusting the pulse width, realizing the precise control of the battery charging and discharging process, which is usually used in the wind power generation system where the output power needs to be adjusted frequently. When the wind speed is too high, the PWM controller can reduce the excitation current by decreasing the pulse width, thus reducing the electromagnetic torque of the generator, so that the generator speed decreases and the output power is reduced to realize uploading.

The primary function of an MPPT controller is to optimize energy capture, which improves the overall efficiency of the system by adjusting the generator voltage and current in real time to track the maximum power point. Although dumping is not possible by itself, in some advanced MPPT controllers, PWM technology is integrated to protect the battery from overcharging. For example, this design is used in this 300W/400W/500W wind turbine controller. The integrated system is capable of both maximum power point tracking and dumping functions, making the system more flexible and efficient.

How the dump load works has a direct impact on the efficiency of wind power generation as it relates to what to do with excess power generation. It not only prevents battery overcharging and reduces energy waste, but also keeps the system running stably. In the future, wind power controllers with dump load will become the mainstream of the market and better serve your green home.

(1).png)

(1).png)